Solution

Semiconductor Packaging Pick-and-Place Machine Mat

-

Semiconductor Packaging Pick-and-Place Machine Material Foolproof Verification Management

✅ Improve material traceability accuracy and efficiency

✅ Realize automated fool-proofing mechanisms

✅ Reduce human errors and optimize manufacturing processes

Problem:

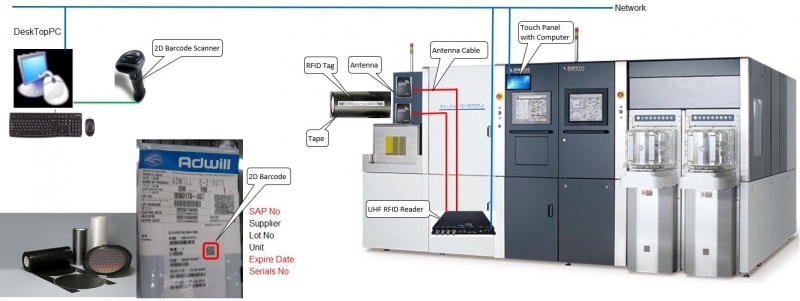

Equipment: Wafer Mount/Taping Machine

Feature: The wafer tape is assigned a material ID for easier verification.

Issue: When switching to a new wafer batch, wafer tape is not replaced with the corresponding BOM number. As a result, the materials used in process do not comply with the process card instructions, leading to defective products and damaging company reputation.

Solution:

• Assign an RFID tag to each wafer tape (linked with batch number and BOM).

• Input the batch number into the MES system to retrieve the corresponding tape material number (BOM).

• RFID automatically reads the tag and verifies the tape material number.

• If a mismatch is detected, an alarm is triggered.

• The system locks the equipment until personnel review and confirm the issue.

Benefits:

By using RFID to replace manual inspection of tape specification labels inside the tape core, the cost of scrapped tape caused by verification can be reduced.

The system automatically reads and verifies the tape material number, preventing the use of incorrect tape and avoiding product scrap losses.

- Headquarters:

- EPC Solutions Taiwan Inc.

- ADD.:3F, No. 49-3, Ln. 2, Sec. 2, Guangfu Rd., East Dist., Hsinchu City 300044, Taiwan (R.O.C.)(Durban Smart Building 1st Phase,Building C)

- TEL:+886-3-5786361

- FAX:+886-3-5771491

- E-mail:julia@epcsi.com.tw

- Hong Kong Branch:

- Sunbest Technology Company Ltd.

- ADD.:Unit B1, 3/F., Mai Shun Industrial Building, 18-24 Kwai Cheong Road, Kwai Chung, N.T., H.K.

- TEL:+852-27702330

- FAX:+852-23886226

- EMAIL:tammy@sunbesttech.com.hk

- Product

- semiconductor tag

- RFID Reader

- RFID Reader Module

- RFID Wristband

- RFID Keyfob

- RFID Tag

- RFID Lock

- RFID 134.2Khz

- RFID 2.45Ghz Product

- RFID Antenna

- Others

- Solution

- RFID Indoor Positioning

- Semiconductor Packaging Pick-and-Place Machine Mat

- RFID smart retail

- RFID production line profile

- RFID baggage management

- RFID product security

- RFID tire management

- RFID Smart Cloud Data Center

- RFID smart healthcare

- RFID intelligent storage terminal

- RFID surveillance System

- RFID Culture and Art

- RFID archives management